|

WHAT ARE PLASTICS ? History In this era of many astonishing industrial developments, probably no industry has under gone such rapid growth and development as the plastics industry. According to most authorities in this field, the plastics industry really began in 1868. A young American printer, named John Wesley Hyatt, was searching for a new material to be used as a substitute for ivory in the making of billiard balls. A $10,000 prize had been offered for such a discovery. He found that cellulose nitrate, formed by the action of nitric acid on cotton cellulose, mixed with camphor and treated with proper amounts of pressure and heat, produced a substance which could be molded into desired shapes. He called his new material "Celluloid."

It was not until almost the beginning of the twentieth century that a second plastic was produced. Adolph Spitteler, a German, mixed sour milk and formaldehyde together to form a material which was really a casein plastic. In 1909, Dr. Leo Baekeland, an American born in Belgium, was trying to produce a synthetic resin. He did this successfully by mixing phenol and formaldehyde together under certain conditions, thus producing the first synthetic resin. This new plastic was called "Bakelite." Many new plastics have been made since "Bakelite." Production of plastics has increased over 2000% since "Bakelite" was first produced, and there are now more than twenty known types. Research along the lines of plastics has given a great impetus to research and invention in many other different fields of endeavor. Millions of dollars are spent yearly in plastics research, trying to find new plastics and to improve the existing ones. Much research will be done in the future to lower the cost of producing plastics so that their consumption will become greater. In spite of the varied and widespread application of plastics in practically every phase of everyday life, the possibilities of this wonderful new material have been by no means exhausted. It seems safe to say that if the application and use of plastics continue to increase at the present rate, we may be living in a "Plastics Age." Terminology A dictionary of technical terms defines the word "plastic" as "capable of being molded or modeled". It defines "plastics" as " nonmetallic moldable compounds and the articles made from them". Recent use has also given the adjective, "plastic," the additional meaning of " made of plastics". An apt definition of plastics has been given by the head of the Monsanto Plastics Research who says, "Plastics are materials that, while being processed, can be pushed into almost any desired shape and then retain that shape." The term "plastics" is a commercial rather than a scientific phraseology, because rubber and glass are easily formed into any desired shape during processing, and retain that shape after cooling. The word "plastics" now generally applies to the synthetic products of chemistry. These chemical products can be cast, molded, or pressed into an unlimited variety of shapes. Classification Plastics, depending on their physical properties, may be classified as thermoplastic or thermosetting materials. Thermoplastic materials can be formed into desired shapes under heat and pressure and become solids on cooling. If they are subjected to the same conditions of heat and pressure, they can be remolded. Thermosetting materials acquire infallibility under heat and pressure and cannot be remolded. Plastics may be classified also according to their chemical sources. The twenty or more known basic types fall into four general groups:

1. cellulose plastics 2. synthetic resin plastics 3. protein plastics 4. natural resins The cellulose plastics include the cellulose nitrates and cellulose acetates. The cellulose nitrate plastics are the oldest in this group, and "Celluloid" is the oldest example. These plastics are made from cotton or wood pulp. The synthetic resins include the phenol formaldehyde, phenolic furfural, urea formaldehyde, vinyl, styrene, and acrylic plastics. These plastics are made from phenol, formaldehyde, urea, acetylene, petroleum, glycerol, and phthalic anhydride. The casein plastics are the most common type in the protein group. They are made from milk. Other protein plastics are made from soy beans, coffee beans, peanuts, and other agricultural products. The natural resins include shellac, asphalt, rosin, amber, and pitch. These materials with fillers are usually cold molded. CAST PHENOLIC RESIN PLASTICS A cast phenolic resin is a cast phenol-formaldehyde resin and is a thermosetting plastic. Phenol and formaldehyde are placed in a large reaction kettle or vessel with a suitable catalyst. A catalyst is a substance which speeds or slows up chemical reaction without undergoing a permanent chemical change itself. In this kettle, the phenol, formaldehyde, and catalyst are subjected to heat for several hours. This process produces a viscous synthetic resin with the consistency of honey. Lead molds are cast about a master pattern or mandrel. The mandrel is made of highly polished steel and is slightly tapered. The steel mandrel is immersed in molten lead at accurately controlled temperature. The mandrel is then withdrawn from the molten lead pot. After it has cooled, the thin lead shell which freezes to the mandrel is removed. The master mandrel may be used hundreds of times to make the lead molds. The lead molds are used only once and then recast.

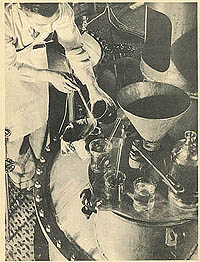

The viscous synthetic resin is drawn from the kettles into hand ladles. It is then poured into the lead molds of various shapes and designs. The lead molds are then placed in curing ovens. In these ovens the castings are subjected to heat, and the liquid resin is changed into an infusible, insoluble material. The cast parts are then removed from the molds with a pneumatic hammer. Cast phenolic resins are supplied in sheets, tubes, rods, and many special shapes. Pieces have been cast that weigh only one-fiftieth of a pound and on special order that weigh as much as one hundred pounds. This type of plastics, because of the wide scope of their color effects and the variety of shapes available, has an infinite variety of uses. The range of application may be from small buttons to radio cabinets. Some of the more common trade names of this type of plastic and the companies manufacturing them are: "Bakelite" Bakelite Corporation "Catalin" Catalin Corporation "Marblette" Marblette Company "Opalon" Monsanto Chemical Company The following is a partial list of the properties of Monsanto Cast Phenolic Resin as giver by the Monsanto Chemical Company:

|